La bola con vástago se utiliza generalmente para válvulas de bola de muñón de alta presión o válvulas de bola criogénicas. Más procesadas y con mayor dificultad de procesamiento, el costo será mayor que el de las bolas normales. A veces, para reducir los costes de producción, los vástagos se pueden soldar con bolas.

Palabras clave:

Bola de válvula con vástago, bola de vástago, bolas de válvula de vástago, bola con vástago.

Características de las bolas de válvula

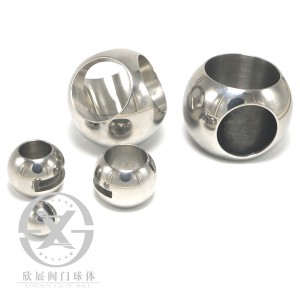

Las dos características más importantes de las bolas de válvula son la redondez y el acabado superficial. La redondez debe controlarse especialmente en la zona crítica de sellado. Podemos fabricar bolas para válvulas con una redondez extremadamente alta y tolerancias de acabado superficial altas.

¿Qué tipos podemos fabricar para bolas de válvulas?

Bolas de válvula montadas sobre muñón o flotantes, bolas de válvula sólidas o huecas, bolas de válvula con asiento blando o de asiento metálico, bolas de válvula con ranuras o con estrías y otras bolas de válvula especiales en cada configuración o bolas modificadas o especificaciones que pueda diseñar.

Pasos de procesamiento:

1: bolas en blanco

2: Prueba PMI y END

3: Tratamiento térmico

4: Prueba de END, corrosión y propiedades de materiales

5: Mecanizado en desbaste

6: Inspección

7: Terminar el mecanizado

8: Inspección

9: Tratamiento superficial

10: Inspección

11: Rectificado y lapeado

12: Inspección final

13: Embalaje y logística

Aplicaciones:

Las bolas de vástago se utilizan principalmente para válvulas de bola de alta presión o válvulas de bola criogénicas.

Mercados principales:

Rusia, Corea del Sur, Canadá, Reino Unido, Taiwán, Polonia, Dinamarca, Alemania, Finlandia, República Checa, España, Italia, India, Brasil, Estados Unidos, Israel, etc.

Embalaje:

Para bolas de válvula de tamaño pequeño: blister, papel plástico, cartón de papel, caja de madera contrachapada.

Para bolas de válvula de gran tamaño: bolsa de burbujas, cartón de papel, caja de madera contrachapada.

Envío:por mar, por aire, por tren, etc.

Pago:Por T/T, L/C.

Ventajas:

- Los pedidos de muestra o los pedidos de seguimiento pequeños pueden ser opcionales

- Instalaciones avanzadas

- Buen sistema de gestión de producción.

- Equipo técnico fuerte

- Precios razonables y rentables.

- Tiempo de entrega pronto

- Buen servicio postventa