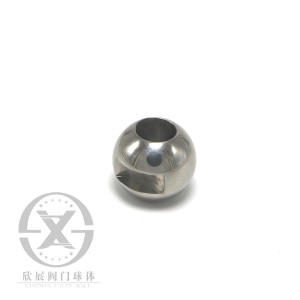

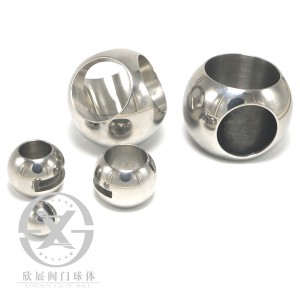

Floating valve balls are used in floating ball valves. The ball is held in the position by the compression of the two elastomeric seats against the ball In a floating ball valve. The ball is free to float inside the valve body. The stem of floating ball valve is connected to a slot at the top of the ball which allows the ball to rotate a quarter turn (90 degrees). The shaft allows for a certain amount of lateral movement of the ball that is generated from the upstream pressure acting on the ball. This small lateral movement, produces a load on the ball that presses it against the downstream seat which improves leak tightness of valve. This type of valve design is capable of bi-directional shut-off. Note that, the floating valve is very difficult to operate when upstream pressure is high.

Valve Spheres Characteristics

The two most important characteristics of the valve balls are the roundness and the surface finish. The roundness must be controlled especially in the critical sealing area. We are able to manufacture valve balls with extremely high roundness and high surface finish tolerances.

What types we can manufacture for valve balls

Floating or trunnion mounted valve balls, solid or hollow valve balls, soft seated or metal seated valve balls, valve balls with slots or with splines, and other special valve balls in every configuration or modified balls or specification that you can design.

Processing Steps

1: Sphere Blanks

2: PMI and NDT Test

3: Heat Treatment

4: NDT, Corrosion and Material Properties Test

5: Rough Machining

6: Inspection

7: Finish Machining

8: Inspection

9: Surface Treatment

10: Inspection

11: Grinding & Lapping

12: Final Inspection

13: Packing & Logistics

Applications

Xinzhan valve balls are used in various ball valves which are used in the fields of petroleum, natural gas, water treatment, medicine and chemical industry, heating, etc.

Major Markets:

Russia, South Korea, Canada, United Kingdom, Taiwan, Poland, Denmark, Germany, Finland, Czech Republic, Spain, Italy, India, Brazil, United States, Israel, etc.

Packaging & Shipment

For small size valve balls: blister box, plastic paper, paper carton, plywood wooden box.

For big size valve balls: bubble bag, paper carton, plywood wooden box.

Shipment: by sea, by air, by train, etc.

Payment

By T/T, L/C.

Advantages:

- Sample orders or small trail orders can be optional

- Advanced facilities

- Good production management system

- Strong technical Team

- Reasonable & cost-effective price prices

- Prompt delivery time

- Good after-sales service