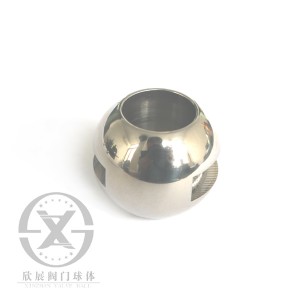

Xinzhan Valve Ball Co., Ltd. yana mai da hankali kan samar da ƙwallon bawul tare da kara ta kayan ƙirƙira.

Mahimman kalmomi:

Bawul ball tare da kara, kara ball, kara bawul bukukuwa, ball tare da kara.

Halayen Valve Balls

Mafi mahimmancin halaye guda biyu na ƙwallan bawul sune zagaye da ƙarshen farfajiya. Dole ne a kula da zagaye na zagaye musamman a wuri mai mahimmanci. Mun sami damar kera bawul bukukuwa da musamman high roundness da high surface gama tolerances.

Waɗanne nau'ikan za mu iya kera don ƙwallon bawul

Ƙwallon ƙafa masu iyo ko ƙwanƙwasa, ƙwallayen bawul masu ƙarfi ko ƙwal, ƙwallayen bawul masu laushi ko wuraren zama na ƙarfe, ƙwallon bawul tare da ramummuka ko tare da splines, da sauran ƙwallayen bawul na musamman a cikin kowane tsari ko ƙwallan da aka gyara ko ƙayyadaddun da za ku iya ƙira.

Matakan Gudanarwa:

1: Barci

2: Gwajin PMI da NDT

3: Maganin zafi

4: NDT, Lalata da Gwajin Kayayyakin Kayayyaki

5: Mashina mara nauyi

6: Dubawa

7: Gama Machining

8: dubawa

9: Maganin Sama

10: Dubawa

11: Nika & Latsawa

12: Binciken Karshe

13: Packing & Logistics

Aikace-aikace:

Ana amfani da ball na Xinzhan a cikin bawul daban-daban waɗanda ake amfani da su a fannonin man fetur, iskar gas, kula da ruwa, magunguna da masana'antar sinadarai, dumama da sauransu.

Manyan Kasuwanni:

Rasha, Koriya ta Kudu, Kanada, United Kingdom, Taiwan, Poland, Denmark, Jamus, Finland, Czech Republic, Spain, Italiya, Indiya, Brazil, Amurka, Isra'ila, da dai sauransu.

Marufi:

Don ƙananan ƙwallan bawul: akwatin blister, takarda filastik, kwandon takarda, akwatin katako na plywood.

Don manyan ƙwallan bawul masu girma: jakar kumfa, kartanin takarda, akwatin katako na plywood.

Kawo:ta teku, ta iska, ta jirgin kasa, da dai sauransu.

Biya:By T/T, L/C.

Amfani:

- Samfuran umarni ko ƙananan umarni na sawu na iya zama na zaɓi

- Na gaba wurare

- Kyakkyawan tsarin gudanarwa na samarwa

- Ƙwararrun Ƙwararrun Ƙwararru

- Ma'ana & farashin farashi mai tsada

- Lokacin isarwa da sauri

- Kyakkyawan sabis na tallace-tallace