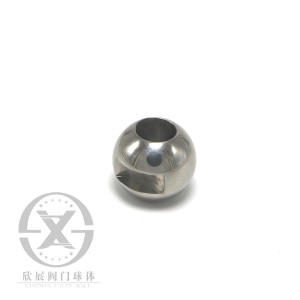

Stainless steel is the most common material to be used for the balls of ball valves. We do the inspection strictly for the incoming material to ensure the material is standard. Stainless steel valve ball is produced by modern manufacturing technology of stainless steel and precision machinery. The product can be formed from welded stainless steel plate ( hollow balls ), or integral forged stainless steel ball blank ( solid balls ).

Keywords of Stainless Steel Valve Spheres

Stainless steel valve balls, stainless steel balls for ball valves, SS valve balls, A182 F304 valve balls, stainless steel hollow valve balls, stainless steel solid valve balls, stainless steel balls for valves, T-port 3 way valve balls, L-port 3 way valve balls, V-port valve balls, forged stainless steel valve balls, stainless steel floating valve balls, steel plate welded hollow valve balls.

Main Types of XINZHAN Valve Spheres

- Floating Type: the ball in floating ball valve will have a slight displacement, that is why we call it floating type. As the ball is floating, so under the pressure of the medium, the floating ball will move and against the downstream seat.

- Trunnion Mounted Type: the ball in trunnion mounted ball valve wont move because the trunnion ball valve ball has another stem at the bottom to fixed the position of the ball. The trunnion type valve balls are mainly used in high pressure conditions and large sizes ball valves.

- Solid Sphere: solid ball is machined from compact casting or forging. Solid ball is normally considered as the best lifetime solution. And solid balls are mainly used in high pressure conditions.

- Hollow Sphere: Hollow ball is made by coil welded steel plate or seamless stainless steel tubes. The hollow ball reduces the load of the spherical surface and the valve seat because of its lighter weight, which helps to extend the service life of the valve seat. For some very large sizes or constructions, solid ball would not be practical.

- Soft Seated: soft seated valve balls are used for soft seated ball valves. The seats are typically composed of thermoplastic components like PTFE. These valves are appropriate for applications in which chemical compatibility is crucial, and in situations where having the tightest seal is important. Soft seats, however, aren’t suitable for processing abrasive or high temperature fluids.

- Metal Seated: Metal seated valve balls are suitable for applications with elevated temperatures or highly abrasive conditions. Metal Seat and Sphere are fabricated from base metals coated with hard chrome, tungsten carbide and Stellite.

- Non-standard customized valve balls are also optional!

Key Points of valve balls

The two most important characteristics of the valve balls are the roundness and the surface finish. The roundness must be controlled especially in the critical sealing area. We are able to manufacture valve balls with extremely high roundness and high surface finish tolerances.

Processing Steps

1: Sphere Blanks

2: PMI and NDT Test

3: Heat Treatment

4: NDT, Corrosion and Material Properties Test

5: Rough Machining

6: Inspection

7: Finish Machining

8: Inspection

9: Surface Treatment

10: Inspection

11: Grinding & Lapping

12: Final Inspection

13: Packing & Logistics

Applications

Xinzhan valve balls are used in various ball valves which are used in the fields of petroleum, natural gas, water treatment, medicine and chemical industry, heating, etc.

Major Markets:

Russia, South Korea, Canada, United Kingdom, Taiwan, Poland, Denmark, Germany, Finland, Czech Republic, Spain, Italy, India, Brazil, United States, Israel, etc.

Packaging & Shipment

For small size valve balls: blister box, plastic paper, paper carton, plywood wooden box.

For big size valve balls: bubble bag, paper carton, plywood wooden box.

Shipment: by sea, by air, by train, etc.

Advantages:

- Sample orders or small trail orders can be optional

- Advanced facilities

- Good production management system

- Strong technical Team

- Reasonable & cost-effective price prices

- Prompt delivery time

- Good after-sales service

We greatly appreciates your positive feedback. If you are not satisfied with our service for any reason, please contact us and we will take every care to help you resolve the problem. If you have any question or concern, please feel free to email us. We will try our best to reply all e-mails within 24 hours during week days.